We Make a Difference in your Industry with our Material Processing Solutions

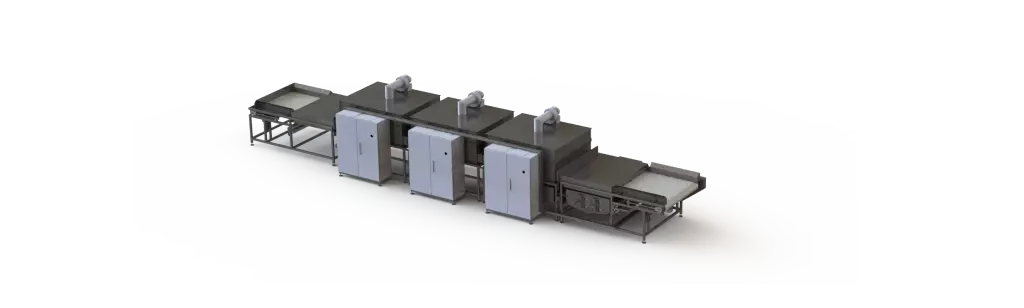

With MET Industrial Microwave Dryers, you get high performance and efficiency thanks to the industrial drying systems we produce specifically for your business.

We Make a Difference in your Industry with our Material Processing Solutions

With MET Industrial Microwave Dryers, you get high performance and efficiency thanks to the industrial drying systems we produce specifically for your business.

Error Rate

Reduction

Increased

Quality

Energy

Efficiency

Productivity

Value-Added

Labor

Decline

MET Advanced Technology Microwave Ovens: Material Processing

What is it?

Material processing in industrial microwaves is the process of using microwaves to heat and process materials in order to change their physical or chemical properties. Industrial microwaves provide fast and efficient heating by generating microwaves that can penetrate deep into the material being processed. This makes it an ideal method for rapidly processing a wide variety of materials, including metals, ceramics, polymers and composites.

How is it done?

To process materials in industrial microwaves, the material is placed in a microwave processing chamber and microwaves are generated and directed towards the material. The microwaves are absorbed by the material and converted into heat, causing the material to heat up. By carefully controlling the power of the microwaves and the time and temperature of the process, it is possible to change the physical or chemical properties of the material.

What Does It Provide?

Industrial microwave material processing is a technology that uses microwaves to heat and process materials in order to change their physical or chemical properties. It provides a fast and efficient method for heating and processing a wide variety of materials, including metals, ceramics, polymers, and composites. Industrial microwave material processing has many applications, including welding, casting, forging, and sintering, and has the potential to revolutionize the materials processing industry.

There are many applications for material processing in industrial microwaves, including welding, casting, forging and sintering. In welding, microwaves can be used to quickly and efficiently heat materials and fuse them together. In casting, microwaves can be used to quickly heat materials such as metals and ceramics to high temperatures for casting. In forging, microwaves can be used to rapidly heat materials such as metals to high temperatures for forging.

In sintering, microwaves can be used to rapidly heat materials such as metals and ceramics to high temperatures for sintering. Overall, material processing in industrial microwaves is a fast, efficient and versatile method for heating and processing a wide variety of materials. It has the potential to revolutionise the materials processing industry and is an important technology to consider for anyone involved in materials processing applications.

Advantages

Industrial microwave processes provide many advantages in material processing operations. Some of the advantages are:

- Fast and Homogenous Heating: Microwave energy penetrates directly into the materials and heats them homogenously from the inside out. This allows the materials to heat up faster and more homogeneously.

- Selective Heat Treatment: Microwave processes heat only the materials that need to be processed and do not affect areas outside the material while it is being processed. This preserves the properties of the materials and prevents unwanted side effects.

- Less Energy Consumption: Microwave processes consume less energy than conventional processes. This reduces processing costs and saves energy.

- Less Processing Time: Microwave energy allows materials to heat up faster. This shortens the processing time and provides a faster production.

- Less Waste: Microwave processes result in less by-product and waste generation. This reduces waste management costs and reduces the environmental impact of the business.

- High Product Quality: Microwave processes preserve the properties of materials and improve the quality of the products obtained as a result of the process.

These advantages have led to industrial microwave processes becoming a popular method in many application areas.

Material Processing with Microwave

As Met Microwave, we are with you in all processes from project design to team rental with our industrial microwave systems that we offer specially for material processing.

Material Processing with Microwave

As Met Microwave, we are with you in all processes from project design to team rental with our industrial microwave systems that we offer specially for material processing.

Sectors Strengthening

Thanks to MET Industrial Microwave Dryers, which we produce specifically for your business and sector, you get high performance and energy efficiency. While you gain time and cost advantage, you also increase your product quality.

Advanced, High-Tech Microwave Oven Systems

Discover Our Next Generation Innovative Products

Let us Project for You

Let us develop and propose a special project for your sector, product, and needs.