Penetration Depths

Penetration Depths

Penetration depth refers to the distance over which one substance or object can penetrate another substance or object. Depending on the specific context and the materials involved, it can be measured in various units such as meters, centimeters, or millimeters.

There are several factors that can affect the depth of penetration of a substance or object, including the properties of the material being penetrated (e.g. density, hardness, porosity), the properties of the penetrating substance or object (e.g. density, hardness, shape), and the conditions under which the penetration occurs (e.g. temperature, pressure, humidity).

Depth of penetration is a key concept in various fields, including materials science, physics, engineering and biology. The study of penetration and impact is relevant to a wide range of applications such as the design of protective materials and structures and the analysis of tissue and cell behaviour.

f = frequency, measured in Hz

εO = absolute dielectric constant (DC) = 8,85×10-12 As/VM

с = 3x1010cm/s speed of light

Ε = electric field strength, measured in V/m

ε = εO * ( εr’ – j εr” ), complex dielectric constant

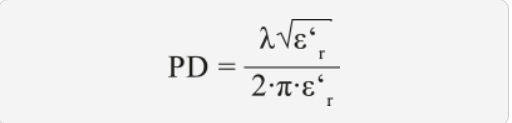

tan δ = εr”/εr’

δ = dielectric loss angle measured in degrees

λ0 = wavelength, measured, λ0 =c / f

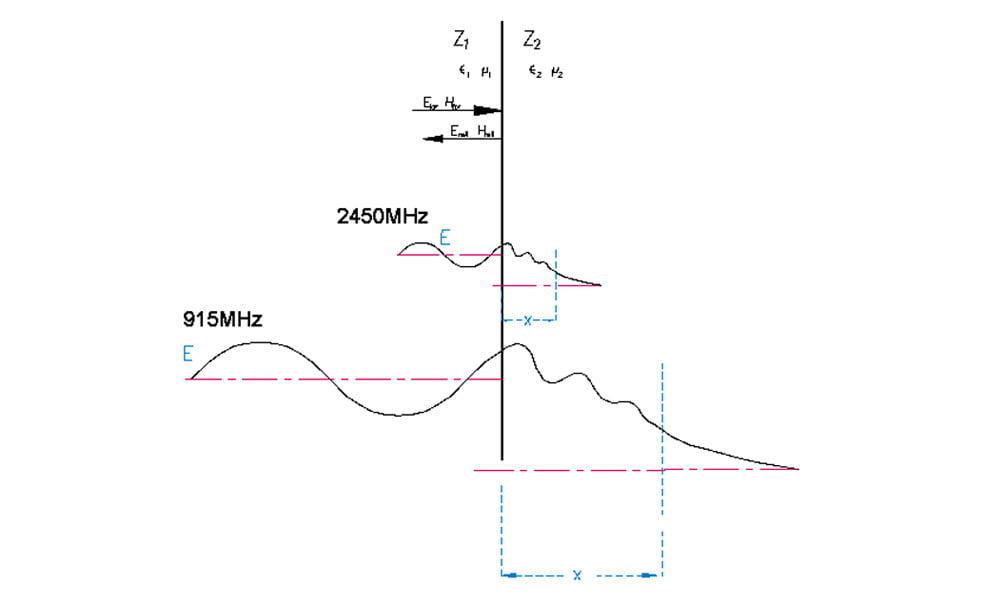

Farklı malzemelerin penetrasyon derinlikleri için değerler Tablo ‘da gösterilmiştir. Literatürde bazen elektrik alan şiddetinin penetrasyon derinliğinin iki kat daha yüksek bir sayı ile verildiği belirtilmelidir.

It is possible that parts with large dimensions and a high loss factor may occasionally overheat an excessively thick coating on the outside. To avoid this, the power density should be chosen to allow sufficient time for significant heat exchange between the boundary and the core. If the thickness of the material is less than the penetration depth, only part of the energy delivered will be absorbed, but this is only true if the unabsorbed energy radiates outwards after leaving the material. However, unused microwave radiation bounces off the metal treatment chamber walls and penetrates the material more than once. Another factor to consider when determining the power density required for microwave heating is maintaining appropriate field strength values inside the application chamber. These are generally much less powerful than dry air breakdown power under atmospheric conditions. To avoid significant damage to both product and equipment, the electric field strength must be limited where vacuum applications are made.

Let us Project for You

Let us develop and propose a special project for your sector, product, and needs.