Microwave Technology

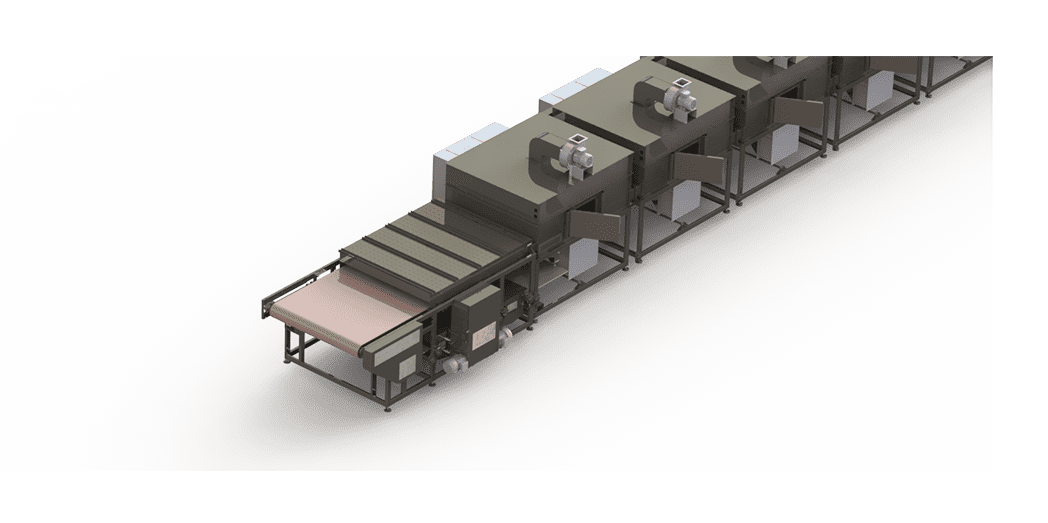

Industrial microwave technology involves the use of microwaves, a type of electromagnetic radiation, for various industrial applications. Microwaves have wavelengths ranging from about one millimetre to one metre and are used in a variety of industries, including food processing, pharmaceuticals, chemicals and wood processing. Microwave energy can penetrate materials and generate heat through a process called dielectric heating. This occurs when microwaves cause molecules in the material to vibrate and generate heat. The depth of penetration and the amount of heat generated depend on the frequency of the microwaves and the electrical properties of the material. Microwaves are used in a variety of industrial applications, including drying, curing, sterilisation and cooking. For example, microwaves can be used to dry wood or paper, sterilise medical instruments or cook food. Industrial microwave systems are designed to be efficient, reliable and easy to maintain and can be used in both batch and continuous processing applications. Some advantages of using industrial microwave technology include the ability to process materials quickly and efficiently, the ability to process heat sensitive materials, and the ability to process materials in a more environmentally friendly manner compared to conventional methods.

Basic Elements for Generating Heat in a Volume

Almost every branch of industry in the world has been influenced by microwave technology. Industrial microwave heating is strongly establishing itself as a viable alternative to conventional heating or is being used to achieve completely new processing efficiency and quality.

Main Products:

Foods, animal feed, chemicals, ceramics, rubber, polymers, composites, pharmaceuticals, wood, plywood, textiles, leather, paper, building materials, silicates, glass, wax, and lubricants are just a few examples.

Processes Implemented

vulcanization, sintering, preheating, hardening, melting, and dehydration.

Let us Project for You

Let us develop and propose a special project for your sector, product and needs.