Industrial Microwave Solutions in the Food Industry

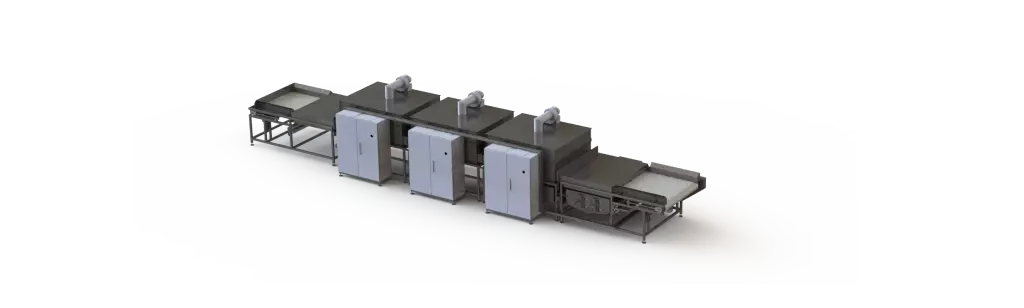

With MET Industrial Microwave Dryers, you get high performance and efficiency thanks to the industrial drying systems we produce specifically for your business.

Industrial Microwave Solutions in the Food Industry

With MET Industrial Microwave Dryers, you get high performance and efficiency thanks to the industrial drying systems we produce specifically for your business.

Error Rate

Reduction

Increased

Quality

Energy

Efficiency

Productivity

Value-Added

Labor

Decline

Food Industry Solutions with Met Advanced Technology Microwave Ovens

What?

We offer solutions for drying, sterilization, moisture balancing, pasteurization and sterilization of dried fruits such as olives, strawberries and pineapples.

How?

We shorten the operating time of food products, and we provide improvements that make a difference in product quality.

Why Us?

We customize our ovens for your business and product and deliver them with successful test results.

Food Processing Industry

In the industrial microwave food industry, microwave energy is used to cook, dry or sterilize food products. Microwave processing can significantly reduce the cooking time and energy consumption of many food products, making it an attractive option for food manufacturers. One of its common applications in the food industry is the microwave drying of fruits, vegetables and grains.

This process involves exposing food products to microwave energy, which heats the water molecules within the food and causes them to evaporate, resulting in faster and more efficient drying. Industrial microwave drying can also help preserve the nutritional value and sensory qualities of food products, as it is typically carried out at lower temperatures than other drying methods. Other applications of industrial microwave technology in the food industry include sterilization of packaged foods, cooking frozen or pre-packaged meals, and drying spices and herbs.

- Pasteurization and sterilization (devitalization) – hyalinization of foods and feeds.

- Defrosting and tempering.

- Inactivation of enzymes and mixture stabilization.

- Utilizing the same scope of advantages of microwave drying applied in many different branches.

- Heat treatment cooking, baking, roasting causes irreversible product changes.

- Preheating can be effectively applied in both industrial and gastronomy processing without any irreversible product changes, further enhanced by using so-called active packaging.

- Pasteurization and sterilization (devitalization) – hyalinization of foods and feeds.

- Defrosting and tempering.

- Inactivation of enzymes and mixture stabilization.

- Utilizing the same scope of advantages of microwave drying applied in many different branches.

- Heat treatment cooking, baking, roasting causes irreversible product changes.

- Preheating can be effectively applied in both industrial and gastronomy processing without any irreversible product changes, further enhanced by using so-called active packaging.

Our Services in the Food Sector

As Met Microwave, we are with you in all processes from project design to team rental with our industrial microwave systems that we offer specifically for the food sector.

Our Services in the Food Sector

As Met Microwave, we are with you in all processes from project design to team rental with our industrial microwave systems that we offer specifically for the food sector.

Sample Applications in the Food Industry

With our high technology and next-generation systems, we provide high efficiency, energy, and time savings in many food products with our microwave dryers in the food industry.

Industrial Microwave Oven Solutions

High-Tech Microwave Oven Systems

Discover Our Next Generation Innovative Products

Let’s Design a Custom Project for You

Let us develop and propose customized projects for your sector, product and needs.