Industrial Microwave Solutions in the Ceramic Industry

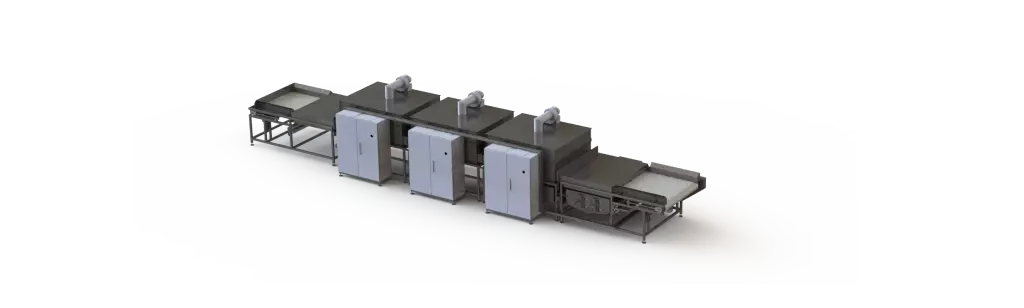

With MET Industrial Microwave Dryers, you get high performance and efficiency thanks to the industrial drying systems we produce specially for your business.

Industrial Microwave Solutions in the Ceramic Industry

With MET Industrial Microwave Dryers, you get high performance and efficiency thanks to the industrial drying systems we produce specially for your business.

Error Rate

Reduction

Increased

Quality

Energy

Efficiency

Productivity

Value-Added

Labor

Decline

Ceramic Industry Solutions with Met Advanced Technology Microwave Ovens

DRYING AND SINTERING OF CERAMIC PRODUCTS

Dielectric Heating

The unique properties of microwave heating have found many applications in the ceramic industry – namely drying, sintering and cleaning from organic matter. Energy is saved compared to conventional methods. Drying time is significantly shorter (in numerical order). The equipment is significantly smaller and the form requirement is respectively lower. Regarding better drying uniformity, there is the possibility to subject the product to various peculiar shapes combining thick and thin walls and cavities. Better production readiness enables flexible order fulfillment and reduces inventory levels. These advantages provide a fast return on investment.

MICROWAVE PRE-DRYING OF HYGIENE CERAMICS

One Reason for Pre-Drying

Due to the relatively high moisture content, the material remains unstable after demolding. The semi-finished product can deform in various ways during handling before being transported to the main tunnel dryer. As a result, it is critical to remove some of the moisture to reduce plasticity. During the microwave pre-drying process, the pores open because the entire depth of the wall is heated, which helps capillary forces push water to the surface. This significantly speeds up both the pre-drying stages and the subsequent main drying process.

Microwave Method with Met

Unlike ceramic material, water absorbs microwave energy. The entire product is heated simultaneously and evenly throughout the water molecule population. Since the surrounding air is not affected by microwaves, the increased temperature causes all water molecules to be driven into the lower pressure area formed on the cold surface. Therefore, no other non-dielectric approach can match the speed and effectiveness of the microwave pre-drying process. During the traditional heating method, heat moves slowly from the surface towards the core while moisture is forced in the opposite direction. This is not only ineffective, but also wastes energy by heating the entire material.

Traditional Method

Unlike ceramic material, water absorbs microwave energy. The entire product is heated simultaneously and evenly throughout the water molecule population. Since the surrounding air is not affected by microwaves, the increased temperature causes all water molecules to be driven into the lower pressure area formed on the cold surface. Therefore, no other non-dielectric approach can match the speed and effectiveness of the microwave pre-drying process. During the traditional heating method, heat moves slowly from the surface towards the core while moisture is forced in the opposite direction. This is not only ineffective, but also wastes energy by heating the entire material.

Operation

The control system allows the drying modes to be configured according to the technician’s requirements. It also monitors perfect performance, reports deviations and records data. Personnel without a diploma can manage the operation. A robot manipulating semi-finished products can be given control. No special procedures are required for the device. An electrician can quickly replace consumables. The manufacturer guarantees post-warranty service, of course, even with the information provided.

Application

The raw material used in the production of bidets and toilets is dependent on a variety of factors such as the shape, size, casting method, manipulation, initial and final moisture content, which results in varying casting times across factories. With the help of microwaves, the process is accelerated in order of size. Using a robotic hand to manipulate the delicate product prevents shaking, and can even be connected to the dryer to achieve automatic operation.

Investment

The control system allows the drying modes to be configured according to the technician’s requirements. It also monitors perfect performance, reports deviations and records data. Personnel without a diploma can manage the operation. A robot manipulating semi-finished products can be given control. No special procedures are required for the device. An electrician can quickly replace consumables. The manufacturer guarantees post-warranty service, of course, even with the information provided.

DRYING SINKS AND SIMPLE SHAPED HYGIENIC CERAMICS

Three Different Options and Methods of Use:

1.Hot air drying is accelerated by microwave preheating, which reduces the length of the day to a single shift.

Unlike ceramic materials, water absorbs microwave radiation and heats evenly throughout the object. Opening the pores through which fluids move by capillary forces requires heating the entire thickness of the wall. Parallel to the temperature increase, the pressure also rises, pushing the water molecules towards low-pressure regions, such as on the surface. By opening the pores, the subsequent hot air allows faster diffusion of water through the wall, typically for tunnel-style drying. Since the microwave power can be adjusted very precisely, it is safe to quickly preheat material that is susceptible to the development of microcracks during this initial drying phase.

2.Microwave Pre-Drying Shape Stabilization

The output of a fresh ceramic casting is susceptible to distortion. After demolding, it is preferable to reduce its excessive plasticity by removing some of the moisture to speed up processing. The time required for different processes varies depending on the raw material, shape, size, casting technique, handling and initial and target wetness of the product. The typical inert time of a fresh casting after demolding is reduced by microwave pre-drying. Also, drying in a facility that is readily accessible takes up extra space that can be better utilized for production.

3.Drying at Humidity Suitable for Baking

Physical variations of the dielectric heating concept relate to the benefits of microwave drying. At every position in the body, water directly absorbs the energy delivered. The surface is not heated by the solid phase or air. Since the thickness of the wall shrinks uniformly, there is no deformation caused by the tension between the hot outer part and the cold inner part. The wall heats up, which accelerates the process of fluid diffusion through the pores. Inside, there is no excess pressure or vapor that can cause damage. No shell is formed with an impermeable coating that prevents evaporation. The device simply switches off when not in use; no standby power is used. No preheating is required, so it is ready for immediate use.

Our Services for the Ceramic Industry

As Met Microwave, we are with you in all processes from project design to team rental with our industrial microwave systems that we offer specially for the ceramic sector.

Our Services for the Ceramic Industry

As Met Microwave, we are with you in all processes from project design to team rental with our industrial microwave systems that we offer specially for the ceramic sector.

Advanced, High-Tech Microwave Oven Systems

Discover Our Next Generation Innovative Products

Industrial Microwave Oven Solutions

Let’s Design a Custom Project for You

Let us develop and propose customized projects for your sector, product and needs.