We make a difference in your sector with our Defrosting and Tempering Solutions.

Weight losses caused by conventional defrosting methods are completely eliminated and your raw material yield increases rapidly.

We make a difference in your sector with our Defrosting and Tempering Solutions.

Weight losses caused by conventional defrosting methods are completely eliminated and your raw material yield increases rapidly.

Error Rate

Reduction

Increased

Quality

Energy

Efficiency

Productivity

Value-Added

Labor

Decline

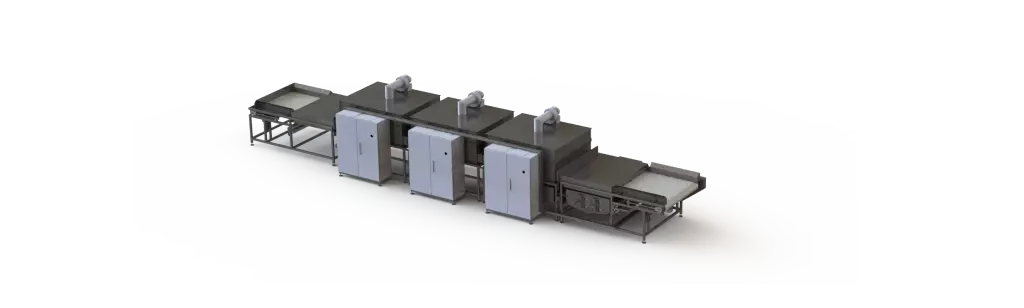

Defrosting and Tempering with Met Advanced Technology Microwave Oven Systems

Microwave Or Radio Frequency

Met Advanced Technology Systems includes both microwave and radio frequency machines, so we will not try to convince you to choose a technology-based solely on the products we sell. We will try to listen to you and analyze your needs. Depending on the characteristics of the materials to be tempered, we will provide you with the highest-performance machine with the right technology and frequency for your application.

Prevent Drop Losses

The speed and uniformity of microwave and radio frequency processing minimize product drip losses and spoilage. By eliminating weight losses caused by conventional defrosting methods, you instantly increase your raw material yield.

Boost Productivity

Thanks to the speed of the process, you remain flexible and can adapt your production in real-time. You also save space in your factory thanks to the small footprint of our equipment, which replaces large annealing or defrosting chambers. Finally, the capacity of our equipment is highly scalable thanks to its modular construction. As your operation grows, our industrial deicing equipment can be easily upgraded.

Improve Quality

The color, weight, flavor, vitamins, and other organoleptic qualities of your calibrated products are preserved during microwave and radio frequency defrosting.

Improve Quality

The color, weight, flavor, vitamins, and other organoleptic qualities of your calibrated products are preserved during microwave and radio frequency defrosting.

Stay Safe

A quick process will prevent bacterial growth. With conventional methods, there is a great danger to food safety as it can take hours or even days for your frozen ingredients to reach the appropriate processing temperature. The final temperature is not precisely controlled and can exceed 0°C. With precise temperature control, microwave and RF tempering can be completed in minutes. Our tunnels give you the flexibility to divide inbound and outbound product flows as required for maximum food safety.

Stay Safe

A quick process will prevent bacterial growth. With conventional methods, there is a great danger to food safety as it can take hours or even days for your frozen ingredients to reach the appropriate processing temperature. The final temperature is not precisely controlled and can exceed 0°C. With precise temperature control, microwave and RF tempering can be completed in minutes. Our tunnels give you the flexibility to divide inbound and outbound product flows as required for maximum food safety.

Defrosting and Tempering with Microwave

At Met Microwave, we are with you in all processes from project design to team rental with our industrial microwave systems that we offer specially for your sector.

Defrosting and Tempering with Microwave

At Met Microwave, we are with you in all processes from project design to team rental with our industrial microwave systems that we offer specially for your sector.

Sectors Strengthening

Thanks to MET Industrial Microwave Dryers, which we produce specifically for your business and sector, you get high performance and energy efficiency. While you gain time and cost advantage, you also increase your product quality.

Advanced, High-Tech Microwave Oven Systems

Discover Our Next Generation Innovative Products

Let us Project for You

Let us develop and propose a special project for your sector, product, and needs.